For my third co-op I worked at Avigilon – a Motorola Solutions Company.

Avigilon is a Vancouver-based security camera company that was bought out by Motorola Solutions in 2018 for a whopping $1.28 billion. I was starting my co-op in early 2020 which is significant for two reasons:

- While the company is relatively new to the Motorola Solutions family, it is still very established. So while some aspects are “start-up”-ish they are also pushing out dozens of new designs per year and have a production line that manufactures millions of units.

- 2020 lockdown happened.

So, I accepted the offer in early January to work here and in late February, everything just kind of shut down. School was now online and friends were getting their exchanges and co-ops cancelled left and right. To say it was a stressful time would be an understatement. The news cycle was a constant blast of updates on disease spread and my email inbox was a strange mix of different company Covid-19 policy updates and assignment submission due dates. The silver lining for me was that classes were essentially done with. Finals were cancelled and a bulk of the weight was shifted to midterms (which I aced) so I patiently waited to see if my summer plans would change.

Luckily for me, my co-op term would proceed as planned – or, I guess, proceed but with a new plan. I get to experience working from home.

working from home

My co-op term started and I virtually met with an amazing team. Surprisingly, there was only about 9 other engineers doing the electrical design for all of the projects.

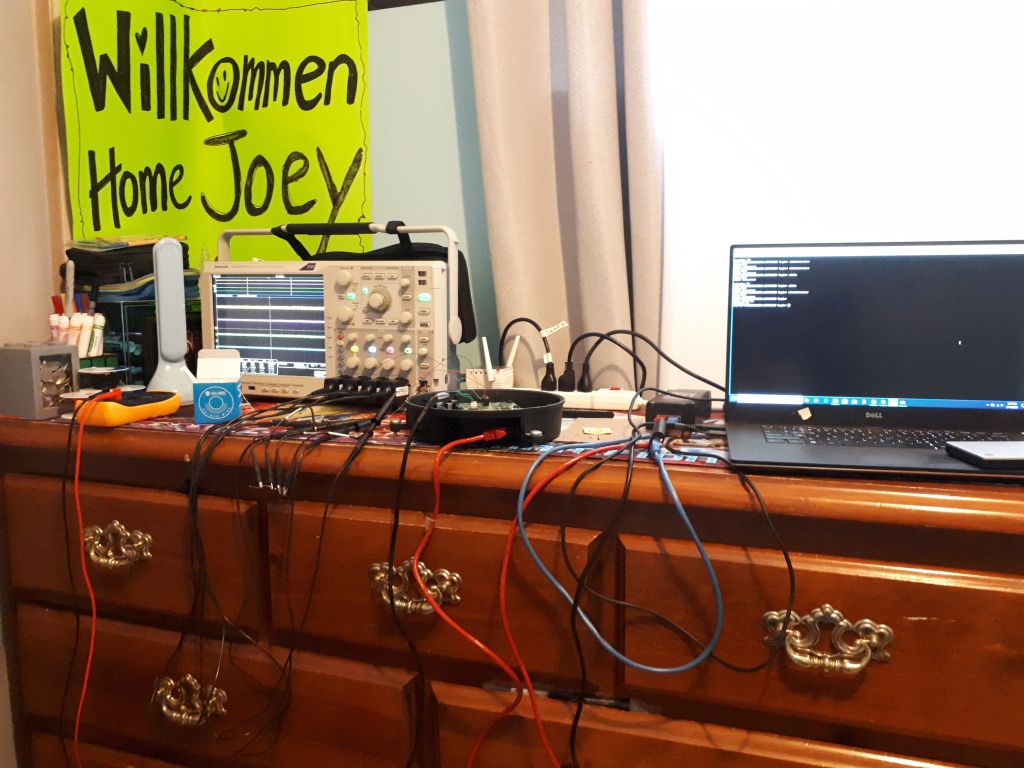

I was shipped a lot of materials and had to transform my room into a makeshift lab. I did some debugging on camera units and learned all about the development tools at our disposal.

This was the first time that I really started to learn about hardware electronics: communication protocols, timing requirements, power sequencing, and more. After finishing up a couple of tickets on some bugs, we were able to very slowly return to work. Since there were still heavy restrictions, I pretty much became the lone person in office every day.

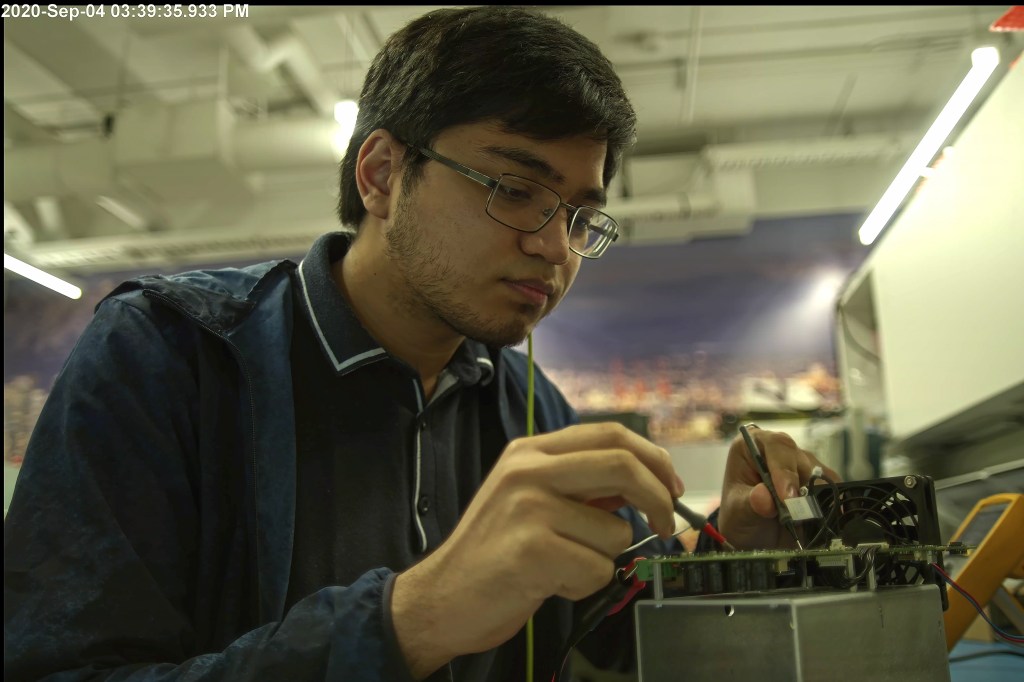

Thus, I took on a lot of the tasks that require tools in our lab – including a lot of rework, testing, and more debugging. This let me hone my skills in component level soldering, running tests with extensive documentation and, of course, debugging.

There were many highlights for both my learning and enjoyment at Avigilon:

- Conducting Electromagnetic Interference/Compatibility (EMI/EMC) testing for the first time, learning about how to design for it and how to properly test electronic devices

- Conducting in-house Hi-Pot testing by putting 2kV of potential into cameras to ensure that they can withstand large spikes in voltage while in the field

- Learning to work with a PLM and managing different library sources in Altium Designer

- Designing a PCB for mass production

- Learning to use Jira to properly document findings within tickets and effectively communicate status updates

- Running Highly Accelerated Life Testing (HALT) on cameras by running them at max capability inside large convection ovens

- (Almost) winning online team trivia

- Playing online board games using table top simulator

- All the great lunch options nearby when working downtown

After 8 months I had learned a significant amount and felt like a strong member of the team. However, it was time to go back to (online) school to finish off my degree. This was an amazing experience and one that really solidified my interest in electrical design.

One of the things that I realized after working at a security camera company: these cameras are everywhere – and once you know what to look for and where to look for it, you’ll never stop seeing them.