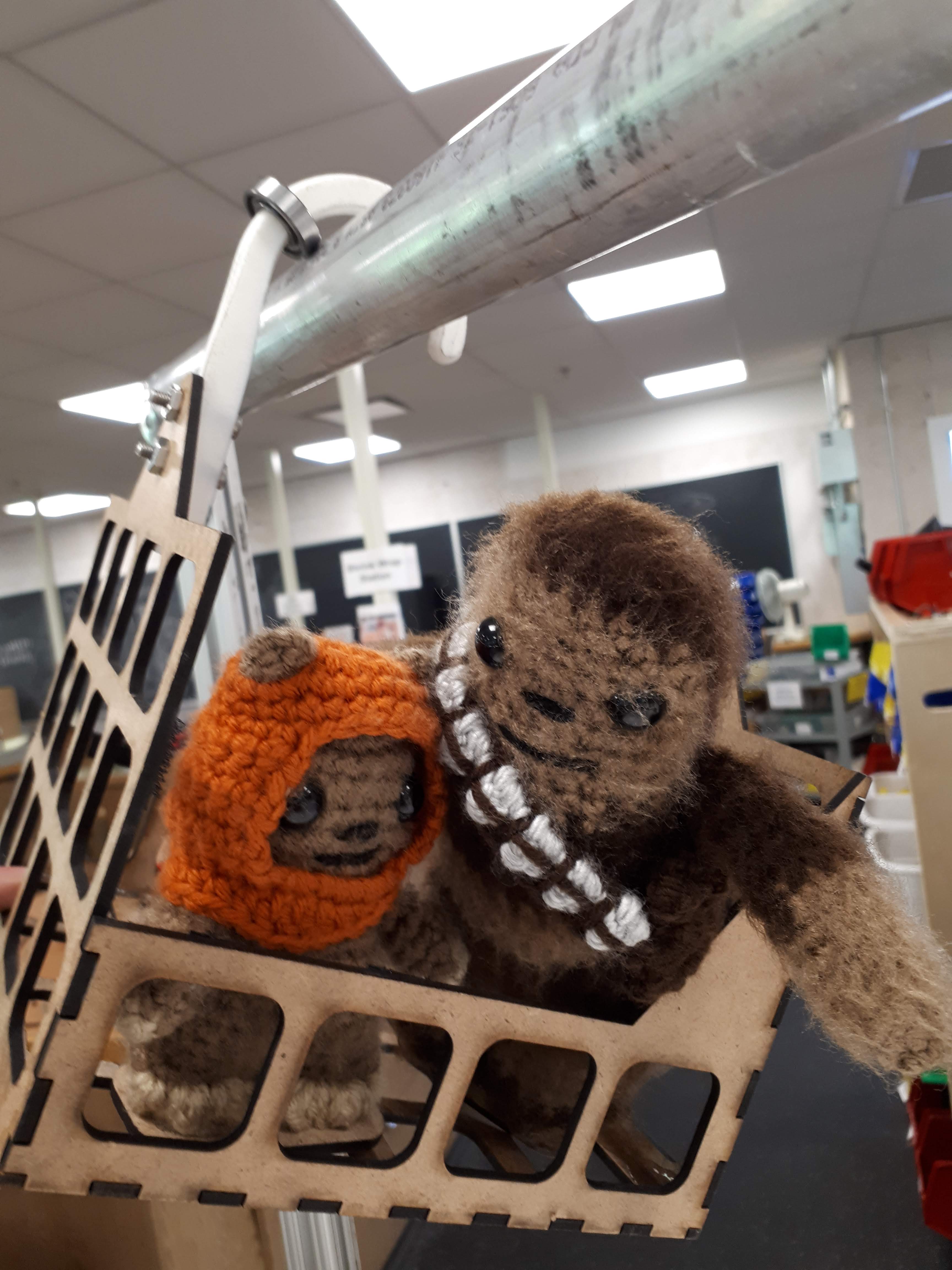

Every summer the newest Engineering Physics students partake in the much anticipated “Robot Summer”. This year’s theme: STAR WARS! Each team must build a robot that can infiltrate the Empire’s secret base with alarmed gates and flooded by stormtroopers. Along the way there are trapped ewoks that you must rescue and if you make it to the end, Chewbacca waits for rescue with the latest plans to destroy the next evil plan that the empire is cooking up.

And did I mention, the entire mission must be done autonomously.

overview

The entire project is done over the course of 6 weeks. In that time we learn everything we need to know to build our entire robot from scratch. This includes:

- Designing every part in CAD

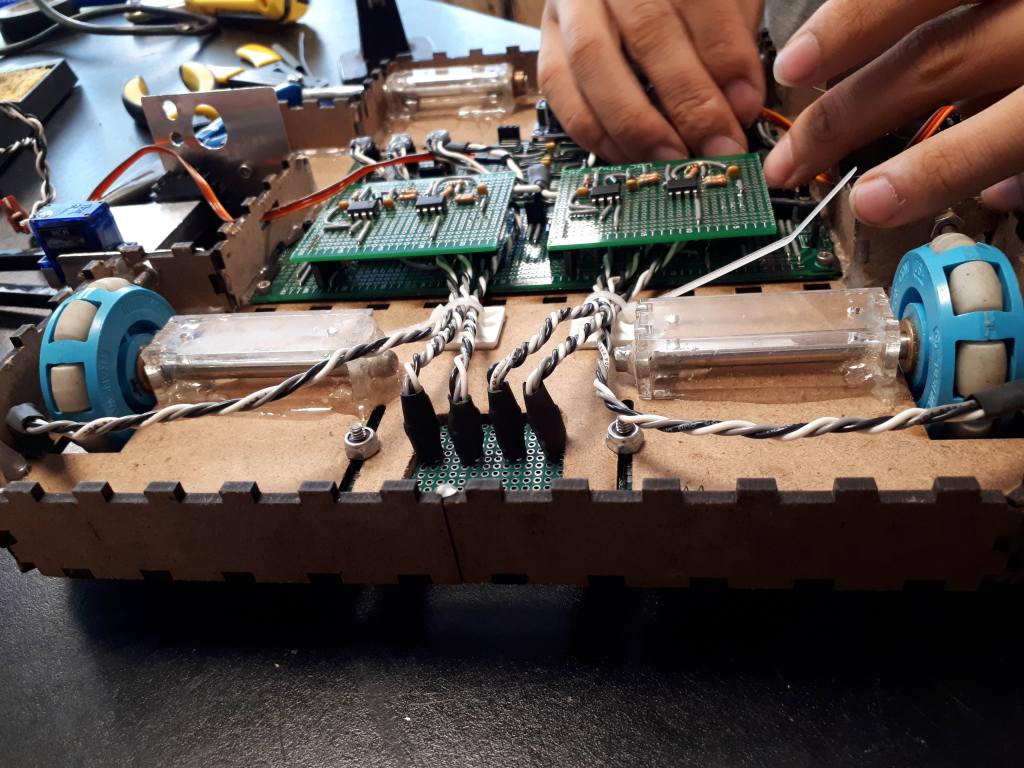

- Fabricating everything with a laser cutter/waterjet cutter/3D printer

- Designing and building our own circuit boards

- Coding all functionality

The obstacles are as follows:

- Navigation, the course is marked by black tape to allow for line-following

- 6 inch gaps to cross

- A gate which alternates between alarmed and inactive, an IR emitter emits different frequencies for each state.

- Ewoks along the way that need to be rescued

- Extra Points gained for getting the ewoks back to the start.

Here is an overview of what the stage looks like:

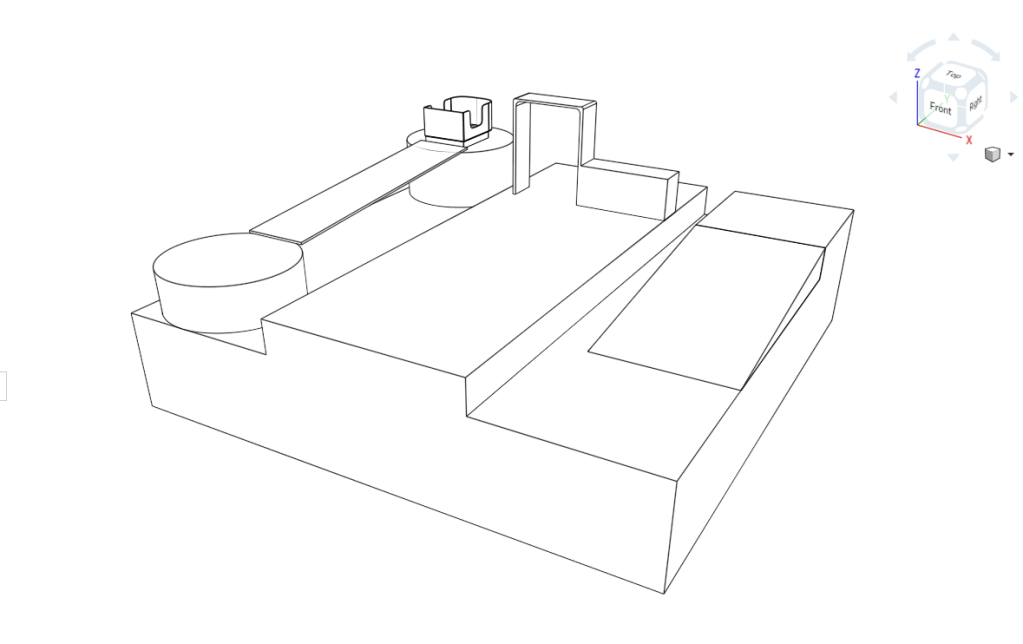

Here is a mockup of the course that I made in CAD to help dimension our robot:

construction

With our goals clear, it was time to build it. I was in charge of mechanical design, I created the chassis with one goal in mind: modularity. The key is that by designing the robot to be modular, we can begin testing one aspect of the design while continuing to design the next. We could have a base driving around while my teammate Kaveh designed the claws to rescue the ewoks. We could test the claws while I designed the basket and lift system to hold them. We could test the basket lift while I designed the bridge deployment system.

This rapid design-test process made it so we were the first to begin testing and discover potential problems earlier. We had a line-following chassis after a week and a half.

This is the third design iteration as well. Overall, we redesigned this chassis 5 times. Undergoing a redesign on a six week project is usually detrimental and a huge time cost. However, because we were able to test very early and all of the other modules fit onto any chassis thanks to the modular design, it was no issue at all. When our robot suffered an unfortunate fall and broken plastic, it only cost half a day to re-cut every piece and have it up and running again.

In the end, we had every module on the robot and it was starting to look complete.

testing

As the robot is to be autonomous, we spent a majority of time on testing the performance. The robot contains several sensors for various methods of detection.

At the front are four pairs of IR LEDs and detectors. This was our line following module. IR LEDs reflect differently on a dark surface compared to a light surface. By detecting the reflection we could tell which part of the robot was on the line. By including four pairs of LEDs/detectors, we could implement a better line-tracking algorithm that could account for sharp turns much better.

There are also two sensors pointing out the front that could detect the presence of nearby ewoks.

In the back was the main processor. It used a simple LCD display so we could edit different variables on the fly without having to upload a new program. We incorporated a clear plastic case to quickly debug issues in the case that something disconnected or broke internally (plus it just looks cooler).

In the final week before the competition, our robot was one of only two in the entire class that could complete the entire course. We coasted through the final week making very small adjustments here and there to try and perfect our strategy as much as possible.

results

Unfortunately, due to technical difficulties and probably overconfidence on our parts, we didn’t win the overall robot competition. We didn’t even qualify out of our heat. Our hard work and ingenuity didn’t go unrecognized, however, as we were proclaimed to be the best prototyped design in the class and received the highest grade for our project.

Overall, we learned a lot of lessons, saw a lot of successes, and had even more failures. It was an experience that saw each of us grow in both technical ability and as individuals finding an identity within a team. These are the types of learning experiences that make me confident that I chose the right career path, the type of learning experience that you couldn’t find anywhere else.

For more, check out the website we made about it